Spunbond and non-woven fabrics are subordinate. There are many production processes for the manufacture of non-woven fabrics, among which spunbond is one of the non-woven production processes (including spunbond, meltblown, hot-rolled, and hydrostatic). It is a non-woven fabric produced by the spunbond method) Non-woven fabrics are polyester, polypropylene, nylon, spandex, acrylic, etc. according to the composition; different compositions will have completely different styles of non-woven fabrics. The spunbond fabric usually refers to polyester spunbond and polypropylene spunbond; and the styles of these two fabrics are very similar, which can be distinguished by high temperature testing.

Non-woven fabrics, also known as non-woven fabrics, are a new generation of environmentally friendly materials, which are water-repellent, breathable, flexible, non-combustible , non-toxic, non-irritating, and rich in colors. If the non-woven fabric is naturally decomposed outdoors, its longest life is only 90 days, and it decomposes within 5 years when placed indoors. It is non-toxic, odorless, and has no leftover substances when burned, so it does not pollute the environment and is suitable for washing.

It directly uses polymer chips, short fibers or filaments to form new fiber products with soft, air-permeable and flat structure through various web forming methods and consolidation technologies. It has environmental protection performance that plastic products do not have, and its natural degradation time is much shorter than that of plastic bags. Therefore, non-woven bags made of non-woven fabrics are also recognized as economical and environmentally friendly shopping bags.

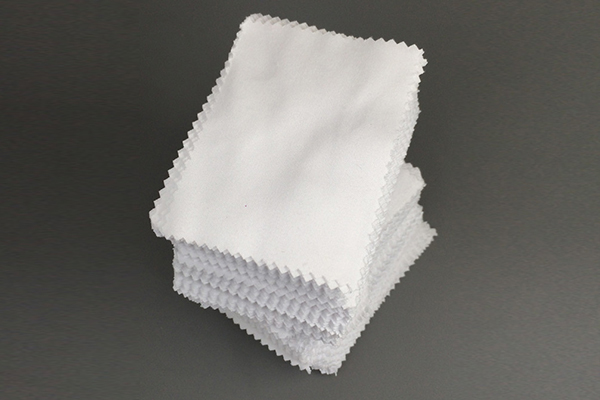

The dust-free cloth is made of 100% polyester fiber double woven, the surface is soft, easy to wipe the sensitive surface, friction does not detach the fiber, has good water absorption and cleaning efficiency. Product cleaning and packaging are completed in the ultra-clean workshop. The optional edge banding of dust-free cloth generally includes: cold cutting, laser edge banding, and ultrasonic edge banding. Microfiber dust-free cloth is generally sealed by laser and ultrasonic; dust-free cloth, dust-free wiping cloth, microfiber dust-free cloth, and microfiber wiping cloth are made of 100% continuous polyester fiber double woven fabric. The surface is soft and can be used When wiping sensitive surfaces, the dust production is low and the friction does not defiber. It has good water absorption and cleaning efficiency. Especially suitable for dust-free purification workshop. The edges of dust-free cloth, dust-free wiping cloth, microfiber dust-free cloth, and microfiber wiping cloth are sealed by the trimming machine. After wiping, no particles and thread ends are left, and the decontamination ability is strong.

English

English Español

Español Deutsch

Deutsch عربى

عربى